Week of 12/1 -12/5

- Dec 4, 2025

- 2 min read

This week, I got a ton of work done on my design. Firstly, I worked on the foot design, which is the last part of the leg. I wanted to make it lightweight since it's the longest piece I have, so I made holes along it. I also added in a spot for screws at the bottom, since I am connecting both halves with pins, but they are not foolproof, and the pieces can still fall apart, so I wanted the extra reinforcement. I went through a couple of different designs, but I ended up with this one, and I think it will work the best. I also left a spot for a rubber foot at the bottom, so it can grip different materials.

My previous choices also made me want to redesign the thigh part, since I will need to reprint it anyway to fit the new motors. With the design I currently have, there is only one bar between the two pieces. This makes it so it is not entirely stable, and also makes it bend more easily. Thus, I added a second bar. This will not only increase the stability, but also make it so the two pieces will not fall apart as easily, since there will be more pins to hold them in place.

This design change was kind of annoying since fusion kept giving me errors, but eventually I got it to work, and now it looks good. I just have to actually print the pieces.

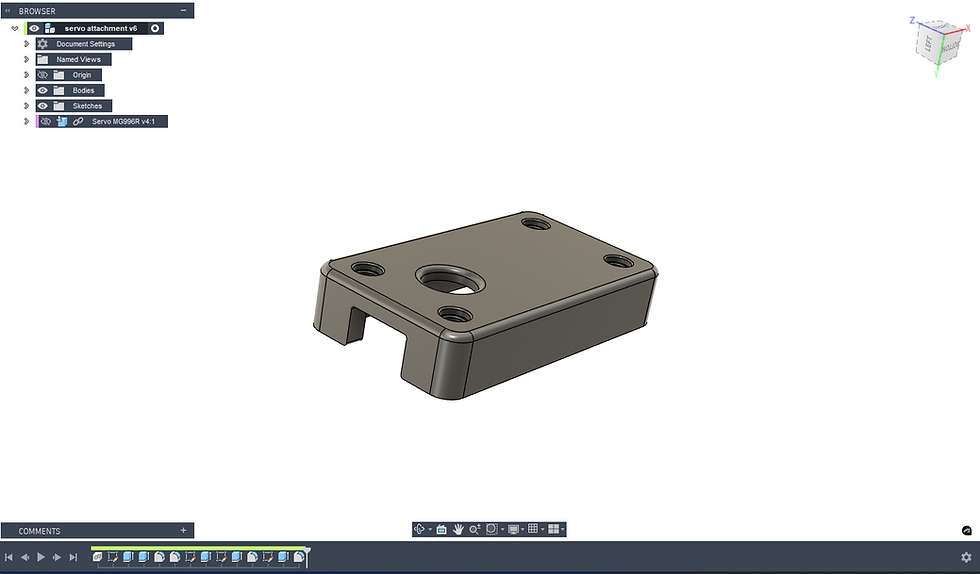

Something else I wanted to address was the motor attachment for the frame part. As I had it, the piece would only attach to one side, and this caused some issues. First of all, it would slightly tilt to one side, which would make the pin slip out more easily when rotating, and secondly, I needed to redesign it anyway to make it a bit larger so that the wire would fit.

To fix these issues, I simply extended it so it covers both sides of the motor and added two screw holes for the other side. I also made the wire divot taller since the wires were further down the motor than I originally thought.

I also printed out the foot once I was able to use the 3d printer, and once it was done, I assembled it, and it came out really well. I am still waiting for the new servo motors to come, so I can't actually attach the motors to the 3d printed parts with screws yet, but even with just the tightness, they already fit very well.

Comments