Week of 10/6 - 10/10

- Oct 10, 2025

- 1 min read

This week, I primarily focused on soldering and crimping in preparation for soldering my entire PCB, and I made significant progress. Firstly, I crimped the hall effect sensor since it was already partially done, and I just needed to change the regular attachment to a polarized attachment.

Then, I tried to crimp the electromagnet wires, but since those wires are larger to keep up with the high current, I had some issues, and I needed an alternative method other than regular pins. I decided to use a screw in terminal with Mr. Christy's recommendation, and it seemed like it was going to work.

Then, I tried actually putting the connector onto the PCB, and I realized that the holes were too far apart, there was a gap in the middle, but I had designed the PCB to have two pins right next to each other. Mr. Christy then suggested a barrel connector, which would solve my issue, so I soldered the wires to that, and it works perfectly.

I also soldered wires onto the switch, and that came out really well, but mr Christy reminded me to use two smaller heat-shrink tubes instead of one big one to prevent short circuits.

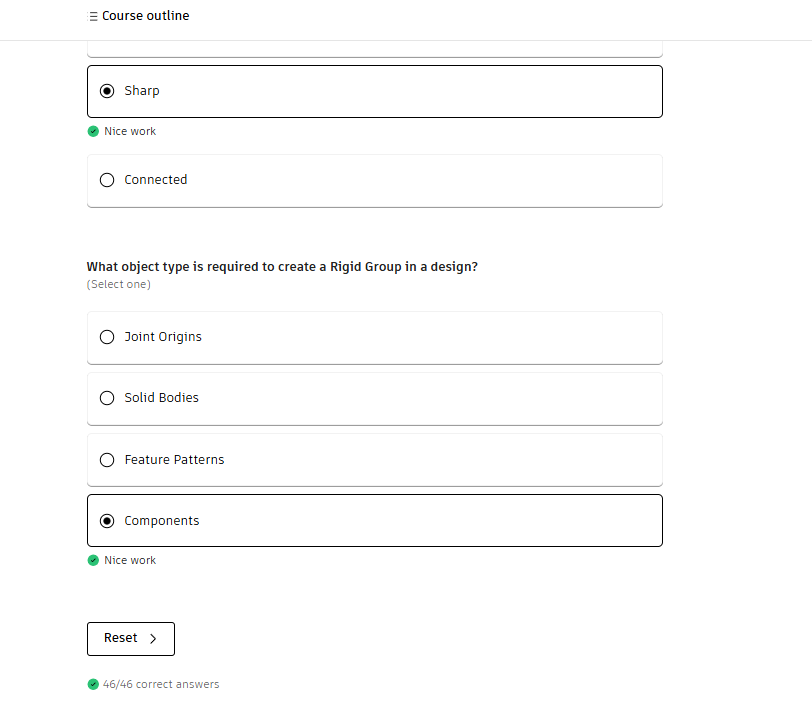

I also completed the CAD course and signed up for the test, so next Monday I will be taking it, and I hope I pass. I feel prepared, though, since I got 100% on the practice test.

Comments